Cell-based assays are becoming an increasingly important part of drug discovery and HTS due to their increased physiological relevance and are widely considered better predictors for in vivo studies.

Although there has been an industry shift towards the utilization of more disease-relevant cell types in screens, there are reasonable concerns regarding the utilization of peristaltic dispensers for cell handling that restrict or prevent their use.

SPT Labtech wanted to determine if these concerns were eased using dragonfly® discovery, its automated, positive displacement, non-contact dispenser.

SPT Labtech established a collaboration with a UK Based Contract Research Organisation (CRO) that supplies drug discovery services to a variety of partners over a broad range of therapeutic areas.

This CRO’s HTS infrastructure consists of fully automated lab work cells and standalone small-scale automation. Despite this, the automation of the setup of cell-based assays continues to be a crucial challenge for their team.

Some dispensers which are commonly employed carry large reagent dead volumes of several milliliters. However, this is not acceptable for specialized cell types.

Further challenges involve uneven cell distribution, compromised cell viability and health due to peristaltic dispensers, and the lack of capacity to change reagent conditions in 1,536-well microplates.

As their site maintains over 40 different validated cell lines in continuous culture at any given time, this CRO requires an automated dispense solution that can provide universally robust and gentle cell plating into 1,536-well microplates.

Through the collaboration with SPT Labtech, the CRO assessed the performance of the dragonfly discovery dispenser and its associated auto-feed reservoir module to overcome these challenges.

Key benefits

- Cells dispensed by dragonfly discovery show excellent cell proliferation and viability for a range of cell types.

- Cell plating was carried out in 1,536-well plates using only 2 µL of reagents.

- Robust nuclear cell counts were confirmed across all 1,536 wells of the plate 24 hours after seeding.

- The auto-feed reservoir module increases the liquid capacity and, consequently, cell plating throughput of the dispenser.

Materials and methods

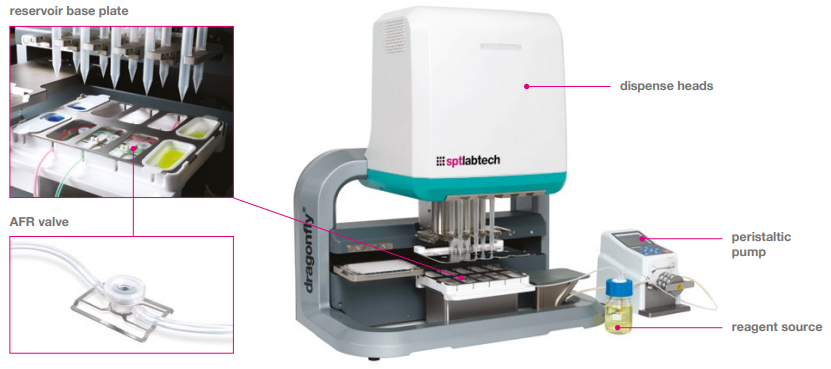

Figure 1. The dragonfly discovery instrument and auto-feed reservoir (AFR) dispense module. The AFR module is compatible with all dragonfly discovery configurations (3/6/10 heads) and increases the reagent capacity per dispense channel over manual reservoirs. AFRs are based around a single-use valve, from which liquid aspiration occurs. It is made of two silicone seals encased in a polypropylene shell and controls the flow of liquid through the input/output tubing, as well as liquid supply to the tip. A peristaltic pump supplies reagents to the AFR valve from a source container, either in continuous closed loop circulation, or to waste. AFR valves have a spring-loaded metal holder that clips securely onto a reagent tray. It is possible to connect up to three AFR valves in sequence and to mix and match manual and AFR reservoirs. Image Credit: SPT Labtech

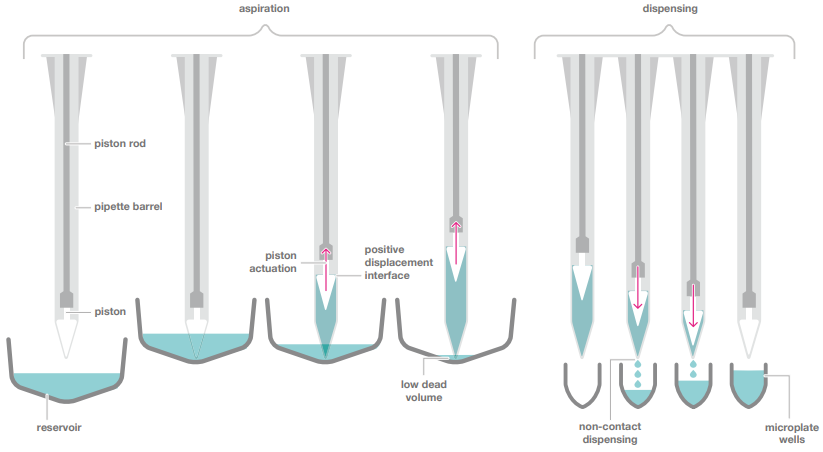

Figure 2. dragonfly discovery aspiration and dispense mechanism. Each liquid channel comprises a tightly sealed plunger that travels vertically within a syringe body. When coupled to the instrument’s piston rod, the positive displacement syringe is formed. The distance and rates of acceleration and deceleration of each piston rod control how and when liquid is aspirated or dispensed. Each positive displacement syringe is independently controlled. Image Credit: SPT Labtech

Technology overview

The dragonfly discovery instrument, as shown in Figure 1, consists of up to 10 dispensing heads inside the top cover that are independently controlled.

The instrument utilizes a unique non-contact, positive displacement mechanism to dispense liquid from disposable tips (as displayed in Figure 2) into either 96, 384, or 1,536-well microplates.

It can carry this process out at speeds faster than 30 seconds per 384-well microplate or quicker than 90 seconds per 1,536-well microplate. Single-use liquid reservoirs are employed to dispense reagents.

For low throughput experiments that concern fewer than five plates, the use of low dead volume reservoirs (1.5 mL capacity, 30 µL dead volume) or standard reservoirs (10 mL capacity, 300 µL dead volume) is advised.

For high throughput experiments, auto-feed reservoirs (as shown in Fig 1) offer a continual supply of reagents from an offline source without the need for reagent replenishment.

Cell culture, plating & analysis

Five cell lines commonly used in different application areas: CHO-Nav (patch clamp screening), CHO-Trk and HT1080 (kinase screening), Neuro2A (neuronal assays) and HepG2 (liver assays) were maintained in live culture according to the cell line vendor’s recommendations for growth medium, cell density, and environmental control.

The cells were brought into suspension on the day of the experiment using trypsinization, and their concentration was adjusted to 2.5 x 105 cells /mL through dilution in a suitable cell culture medium.

The dragonfly discovery instrument was used to dispense 2 µL (i.e. 500 cells) of each cell suspension into 1536-well microplates (CellCarrier Ultra, Perkin Elmer 6004550).

Two replicate plates of cells were seeded for each cell line. The first plate comprised cells drawn from standard dragonfly discovery reservoirs, while the second plate comprised cells drawn from auto-feed reservoirs.

Following this, the cells were grown for 24 hours at a temperature of 37 ºC and 5% CO2 in a humidified incubator. They were subsequently stained for 30 minutes through the addition of propidium iodide (1:1000 dilution, Thermo Fischer Scientific P3566) and 2 µL of Hoechst 33342 (1:5000 dilution, Gibco H3570).

An InCell 2200 imaging system (GE Healthcare) was utilized to image the plates. They were then analyzed using Cell Profiler (www.cellprofiler.org) to establish cell counts and the percentage of viable cells.

Results

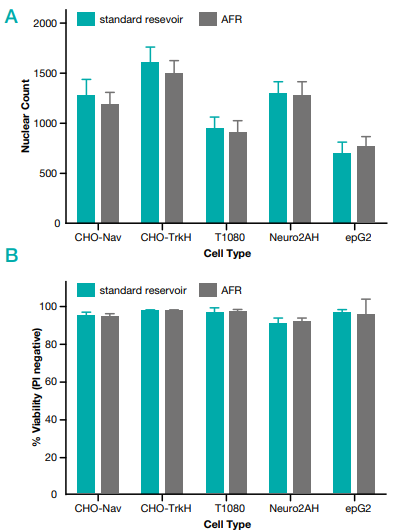

Figure 3. (A) Cell count and (B) % viability 24h after cell seeding with dragonfly® discovery Values represent mean ± SD (n=1536 wells). Image Credit: SPT Labtech

Figure 3 displays a comparison between the nuclear count and the percentage of viable cells dispensed using the dragonfly discovery for all five cell lines.

For each cell line, no difference was observed for either of these figures when comparing cells drawn from AFR reservoirs to cells drawn from manual reservoirs. These figures were also similar to those of cells dispensed by peristaltic dispensers.

About SPT Labtech

We design and manufacture robust, reliable and easy-to-use solutions for life science

We enable life scientists through collaboration, deep application knowledge, and leading engineering to accelerate research and make a difference together. We offer a portfolio of products within sample management, liquid handling, and multiplexed detection that minimize assay volumes, reduce material handling costs and put the discovery tools back in the hands of the scientist.

At the heart of what we do

Many of our innovations have been born out of the desire to create solutions to existing customer problems; and it’s this ethos that drives SPT Labtech’s R&D efforts. Our strengths come from the trust our customers have with us to develop truly unique, automated technologies to meet their needs. We combine cutting edge science with first-rate engineering to put customers at the heart of everything we do.

A problem-solving state of mind

The substantial breadth of expertise within our company enables us to be involved in the full life cycle of our products from the initial design concept, mechanical and software engineering and prototyping, to final manufacture and sale. These qualities allow us to offer the best possible technical and mechanical support to all the equipment that we supply, hence maintaining excellent client relationships.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.